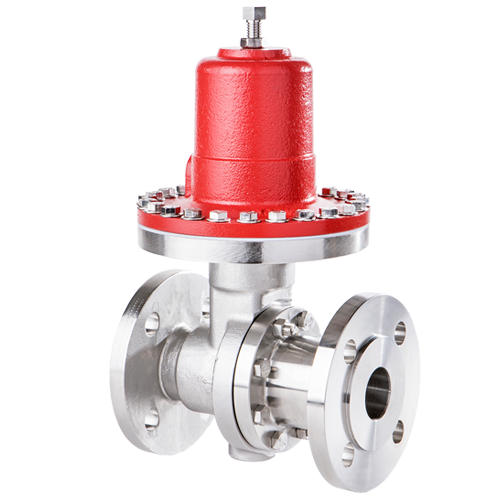

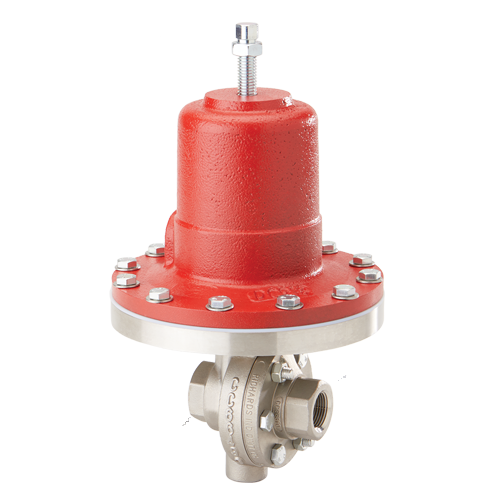

Mark 50 Series

Self-Operated Back Pressure Regulator

The Mark 50 Series handles a broad range of applications including steam, water, oil, gas, air and chemicals. Excellent capacity and the sliding gate trim enables the Mark 50 to quickly and accurately regulate upstream pressure, preventing over-pressure situations.

Sizing: 1/4″ – 4″ (DN8 – DN100)

Cv (Kv): up to 200 (up to 172)

The Mark 50 are available for Next Business Day shipment. — See Jordan Valve express below for more details.

- Sliding Gate Trim — Unique seat design provides unsurpassed trim life and accuracy

- Fast Response — The short stroke of the sliding gate means fast response to changes in process conditions, resulting in less offset in pressure

- Straight-Through Flow — The flow is straight through the valve seats and body. Direction of the disc travel is at right angles with the flow, not opposed to the direction of the flow. Thus the flow does not unbalance the seats

- Quiet Operation — The design of the Sliding Gate seats make them quieter than other types of regulators. The disc and plate are always in contact, which eliminates chattering. Straight-through flow minimizes turbulence

- Minimum Maintenance — The Mark 50 sliding gate seats require no special tools for disassembly. The seats are pre-lapped at the factory and are self-lapping while in operation ensuring a continual tight shutoff

- Sizes: 1/4″ – 4″ (DN8 – DN100)

- Cv (Kv): up to 200 (up to 172)

- Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

- Setpoint: MK50: 0.5 to 150 psi (0,03 to 10,3 bar); MK50HP: 75 to 450 psi (5,2 to 31,0 bar)

- Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel, Cast Iron

- End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Learn more about the sliding gate seat design by watching these videos.

- EC Declaration of Conformity/PED:

Mark 50: 1-1/4″ – 4″ - CRN (Canadian Registration Number)

Mark 50: 1/4″ – 4″

Mark 50QC: 1/4″ – 2″ - UL Listed

- ATEX Certified

1/4″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

1/4″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

3/8″ Mark 50 Series Carbon and Stainless Steel with FNPT Ends

3/8″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Ends

1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Ends

1/2″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

3/4″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

3/4″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

3/4″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

3/4″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

3/4″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

1″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1-1/4″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1-1/4″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1-1/4″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1-1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

1-1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

1-1/2″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

1-1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1-1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1-1/2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

2″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

2″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

2″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

2″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

2″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

2-1/2″ Mark 50 Series All Materials with Integral 300# Flanged Ends

2-1/2″ Mark 50 Series All Materials with Intergral 150# Flanged Ends

3″ Mark 50 Series All Materials with Integral 300# Flanged Ends

3″ Mark 50 Series All Materials with Integral 150# Flanged Ends

4″ Mark 50 Series All Materials with Integral 300# Flanged Ends

4″ Mark 50 Series All Materials with Integral 150# Flanged Ends

The Mark 50 are available for Next Business Day shipment.

Mark 50 Details:

Sizes: 1/2″- 2″

SST/Jorlon diaphragm, Standard Cv and 1 reduction, FNPT end connection, HP option 2″ and under, 150# ANSI Flange for CS or SST bodies. DIN flanges for CS or SST bodies (DN25 to DN50).

Some exclusions may apply.

Your List

Email List

Get A Quote

FAQs

1. Should the seat on the Mark 50 back pressure regulator be opened or closed when the valve is not operating?

On a Mark 50 and any size back pressure regulator that has the sliding gate seat, the valve will be stroked down and the seat will be closed when it’s not opening.

Learn more about adjusting the seat on your Mark 50 back pressure regulator here.

2. How can I disassemble and repair my Mark 50 back pressure regulator?

To learn how to disassemble and repair the Mark 50 series back pressure regulator, watch our instructional video.

Visit our resource page for more product installation and maintenance videos.

How will I know if I have the correct flow direction?

There will be an arrow cast into the side of the body of the Mark 50 series back pressure regulator, this arrow has to always be pointed in the direction that is going with the flow, not against it.

Watch our Flow Direction help video for more information.

Related Products

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.