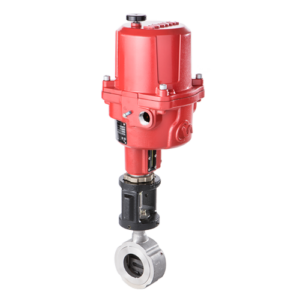

Mark 75MV Series

Wafer Style, Motor Operated

The Mark 75MV wafer style control valve was developed by Jordan Valve as the next generation of control valves. Featuring all the benefits of the time tested sliding gate design, in a lightweight, compact wafer-style body, the Mark 75MV dramatically reduces the size and weight of conventional control valves. The Mark 75MV offers a variety of design features that help provide the superior performance customers expect from Jordan Valve.

- Easy installation between flanges with wafer body

- High flow rates

- Self cleaning, self lapping seats

- Reduced noise compared to conventional globe/cage valves

- More resistant to cavitation / flashing with straight through, wafer design

- Sizes: 1″ through 8″ (DN25 through DN200); 1″ through 6″ (DN25 through DNDN150) ANSI 150#/300# (PN25/40) Class Wafer Style Valves (bolt-around); 8″ (DN200) ANSI 150# (PN25) Class Wafer Style Valves (bolt-thru)

- Seat Materials: Jorcote/316SS (standard); Jorcote with 303SS (optional)

- Shutoff: ANSI Class IV tightness

- Ranges: 4-20 mA; 0 – 10V

- Action: Direct, Reverse

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Learn more about the sliding gate seat design by watching these videos.

CRN (Canadian Registration Number)

ATEX Certified

Your List

Email List

Get A Quote

Related Products

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.