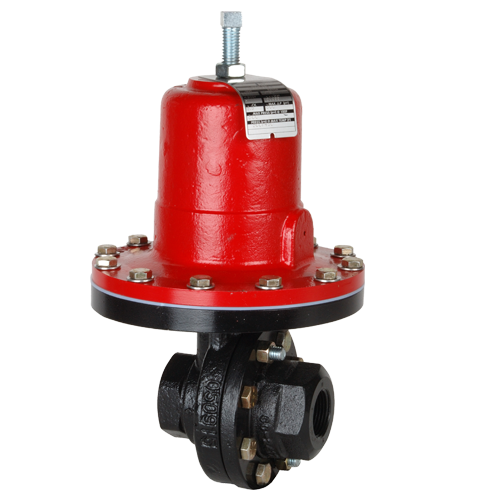

Mark 65 Series

Downstream Vacuum Regulators

The Mark 65 Series is ideal for steam, water, oil, gas, air and chemical services. The vacuum regulators control very accurately and shutoff tightly to maintain the proper vacuum setting. They are used to maintain vacuums at predetermined settings and to regulate vacuum on evaporators, cookers, grinding fixtures, milling machines, altitude chambers and other vacuum systems.

- Sliding Gate Seats offer straight-through flow for reduced turbulence and quiet operation, short stroke for fast response and accurate regulation, tight shutoff, and easily interchangeable Cv’s

- All metal-to-metal contacts – No gaskets, o-rings, or elastomer parts to wear out

- Compact design and simple construction allows fast, simple installation and easy maintenance

Sizes: 1/2″ – 2″ (DN15 – DN50)

Cv (Kv): up to 30 (up to 25,8)

Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

Vacuum Range: 1″ Hg to 25″ Hg vacuum (0,035 to 0,886 kg/cm2)

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Learn more about the sliding gate seat design by watching these videos.

- EC Declaration of Conformity/PED:

Mark 65: 1-1/4″ – 4″ - CRN Number

Mark 65: 1/4″ – 2″ - ATEX Certified

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.