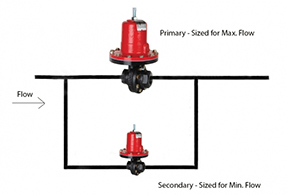

Regulators in Parallel

When are two regulators in parallel a solution? Read on.

When sizing regulators, many manufacturers will suggest selecting a Cv that will allow the regulator to operate between 30% and 70% of capacity, but we all know there will be applications where the minimum flow and maximum flow will make a Cv selection that will operate between 30% and 70% capacity impossible.

The solution: use two regulators in parallel.

The larger regulator (we will call it the “primary”) will handle flows up to the customer’s maximum, so select a Cv which will have the primary at 70% capacity at maximum flow. This regulator will be controlling the downstream pressure until the flow drops to below about 30% of its capacity, which will still be more than the customer’s minimum. Once the primary gets down to about 30% capacity, the smaller regulator (we will call this one the “secondary”) will take over to maintain downstream pressure control down to the minimum required flow. The secondary should be sized so that it will be able to handle the minimum flow adequately, but still be able to have some overlap with the operating range of the primary.

During the overlap period where pressure control is in transition from one regulator to the other, there could be a tendency for them to “fight” each other. To prevent this, stagger the set points so that the primary is set per the customer’s specification, and the secondary is set about 3 to 5 psi higher. This will allow the primary to close during periods of low flow so that the secondary is in control.