Using API 2000 for Tank Blanketing Valve Sizing

Jordan Valve API 2000 flow calculator

Tank Blanketing

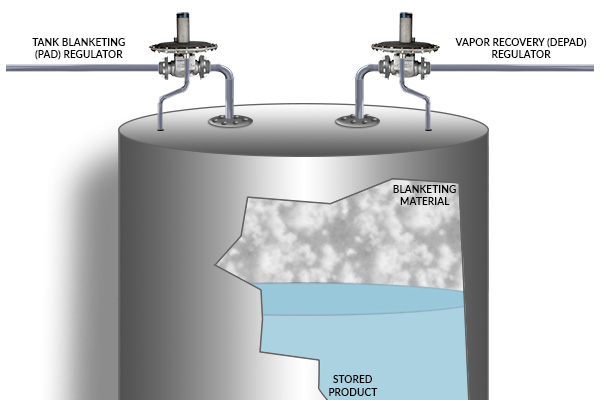

Tank blanketing is the process of providing and maintaining a blanket or pad of gas above the liquid level in a closed tank. The pressures are usually extremely low; less than one psi.

Padding is the process of adding blanket gas into the tank’s vapor space (in-breathing), and maintaining its pressure, thereby its gas blanket. It is known by many names including inert gas blanketing, nitrogen blanketing, or makeup.

When closed (pipe away) venting is provided, that process is often referred to as de-padding. This process removes gas from the tank’s vapor space in cases where the pressure in the gas space increases (out-breathing).

These two operations may also be called “make-up” (padding) and “vent” (de-padding). Jordan Valve has a family of tank blanketing valves designed specifically for this application.

Figure 1: Jordan Valve tank blanketing and vapor recovery valves are sized to maintain blanketing material at optimal pressure

The blanketing gas pressure in the tank changes as liquid is pumped in or out, or as blanketing gas moves into or out of a tank when vapors contract or condense due to temperature changes (thermal breathing). Tank padding and de-padding regulators (also called tank blanketing regulators) are used to maintain the gas pressure within limits as these changes occur. Proper padding regulator sizing is critical to optimizing pressure regulation in the blanketing process. Determining the proper size of a tank blanket regulator for your process involves understanding in-breathing and out-breathing of the system.

What is API 2000?

The American Petroleum Institute (API) developed a standard in 1952, called API STD 2000, to address the tank blanket valve size requirements. The scope has not changed in 70 years, but parameters in the flow calculations have changed over time. In-breathing and out-breathing flow calculations are determined using the API 2000 Standard.

Description From the API:

“This standard covers the normal and emergency vapor venting requirements for aboveground liquid petroleum or petroleum products storage tanks and aboveground and underground refrigerated storage tanks designed for operation at pressures from full vacuum through 103.4 kPa (gage) (15 psig). Discussed in this standard are the causes of overpressure and vacuum; determination of venting requirements; means of venting; selection and installation of venting devices; and testing and marking of relief devices.

This standard is intended for tanks containing petroleum and petroleum products, but it can also be applied to tanks containing other liquids; however, it is necessary to use sound engineering analysis and judgment whenever this standard is applied to other liquids.

This standard does not apply to external floating-roof tanks.”

API 2000 5th Edition is the most widely used today.

The 5th Edition was written as a basis for the pressure control of hydrocarbons in low pressure tanks as well as industrial tanks. The key points addressed are Tank Volume, Pump In / Out (Liquid Flow), and Temperature change.

API 2000 6th Edition was updated in 2009

Updates to the 6th Edition:

- New calculation method.

- 5th Edition method became 6th Edition Appendix A.

Notable additions in the 6th Edition:

- C-Factor and Y-Factor added to the calculations to account for latitude & vapor pressure

- C-factor used for in-breathing flow – considers latitude, vapor pressure, and average storage temperature.

- Y-factor used for out-breathing flow – considers latitude.

API 2000 7th Edition was updated in 2014

- The fundamentals, Liquid flow and thermal change, remain unchanged. This means that liquid flow (or pump-in and pump-out) and changes to temperature still form the fundamentals to the regulator sizing calculations

- C-Factor and Y-Factor remain unchanged

Effect of the New Guidelines

Newer editions often result in greater flow requirements, particularly in-breathing. These requirements can be substantial depending on the C-Factor.

How to Use API 2000 for Tank Blanket Regulator Sizing

Calculated in-breathing and out-breathing from API 2000 are the inputs required for tank padding and de-padding regulator sizing, respectively.

Step 1 – Using API 2000 Calculator Tool to Determine Gas Flow

Use the following API 2000 calculator to determine the Tank Blanketing Regulator Flow (PRV – padding) or Vapor Recovery Regulator Flow (BPRV – depadding).

Step 2 – Using Jordan Valve Sizing Tools to Determine the Proper Tank Blanket Valve Size

Once you have calculated the required tank blanketing regulator flow, use the Jordan Valve JVCV Sizing Program or the Flow Capacity Charts contained in the Jordan Valve Data sheets, linked below.

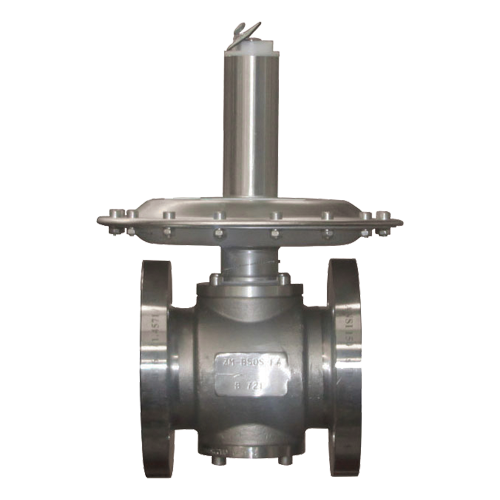

Mark 508 Series Gas Back Pressure Regulators

Mark 508 Series Gas Back Pressure Regulators  Mark 518 Series Low Pressure Back Pressure Regulators

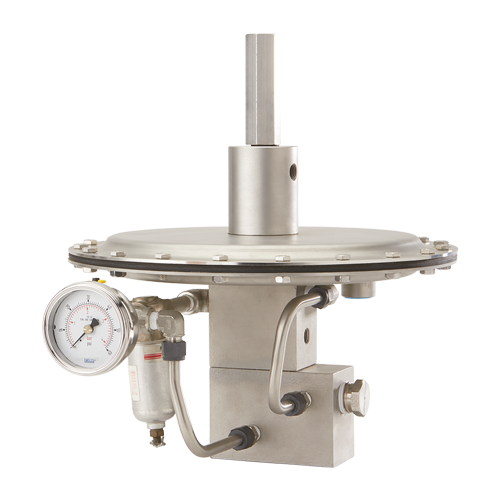

Mark 518 Series Low Pressure Back Pressure Regulators  Mark 695X Series Direct Operated Tank Padding Regulator

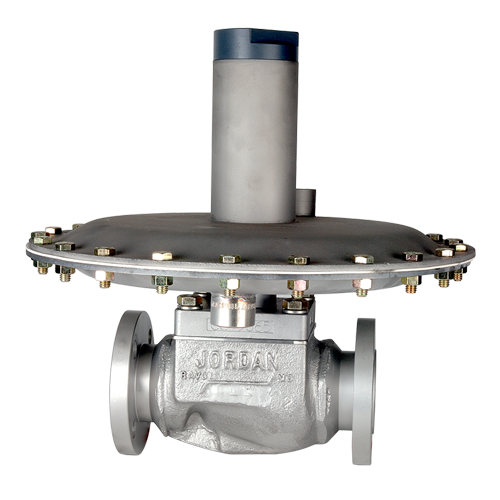

Mark 695X Series Direct Operated Tank Padding Regulator  Mark 695 Series (3/4″ – 1″) Piloted Tank Padding Regulator

Mark 695 Series (3/4″ – 1″) Piloted Tank Padding Regulator