How Do Industrial Regulators Work?

Interested in knowing how industrial regulators work? This is the blog post for you.

A regulator does not need power, instrument air, or any other electronic or pneumatic control devices. Let’s discuss why that is so.

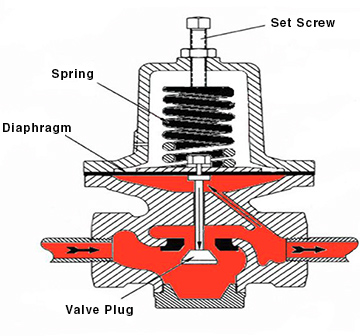

A regulator is a classic force balance machine. Two forces are set up in opposition, and as the balance between the two forces change, different actions take place. If we look at the simple diagram below, we see a set screw, spring, diaphragm, and plug.

The spring and the diaphragm represent the two opposing forces, and the plug acts on the balance between the two. We use the set screw to show the regulator how much pressure we want by turning it to compress the spring. A compressed spring generates a force tending to push downward which in turn opens the plug and results in more flow. As the flow builds up pressure downstream, that pressure acts as an upward force on the diaphragm. This upwards force balances the downward force of the spring. The plug stops moving toward open and the flow and the pressure are now balanced.

Now let’s suppose the downstream demand for flow decreases causing more pressure to build in the downstream line. This will upset our force balance. The increased downstream pressure will exert more upward force on the diaphragm, causing the plug to move toward closed. This limits the flow to prevent further pressure build up. As the diaphragm continues to move upward, the spring is being further compressed, and the downward force it exerts increases. Once the downward force from the spring equals the upward force from the diaphragm, we are now back in the force balance condition and the flow and the pressure are now balanced once more.