What Is Tank Blanketing?

Learn the basics about tank blanketing. Read on!

What is Tank Blanketing?

Tank Blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. Nitrogen is often the tank blanketing gas of choice due to its inert properties, availability, and relatively low cost.

Why is tank blanketing Important?

Blanketing protects people, the environment, the product, and equipment. If the media in the tank is combustible, nitrogen blanketing removes the oxygen and prevents combustion. By eliminating oxygen and water in the vapor space, blanketing protects food and other sensitive products from oxidation, water absorption, contamination, or evaporation. Removing oxygen also reduces corrosion caused by oxidation, helping to maintain the integrity of the tank. Vapor recovery, as part of the tank blanketing process, prevents harmful vapors from escaping into the atmosphere.

Which Industries Use Tank Blanketing?

Virtually all the process industries use tank blanketing. The bulk of tank blanketing applications are found in the Chemical, Petrochemical and Refining Industries with a smaller percentage in Food & Beverage, Biopharmaceutical, Personal Care, Cosmetics and Semiconductor.

A variety of products are protected by gas blanketing including but not limited to adhesives, catalysts, chemicals, deionized water, fats and oils, flavors, foods, fragrances, fuels, industrial coatings, inks, juices, pharmaceuticals, photographic chemicals, sealants, soaps, solvents, volatile combustibles, and water for injection.

The Jordan Valve Mark 608 gas pressure regulator is used on large tank blanketing applications to control the flow of the blanketing gas into the tank to maintain the proper positive pressure.

How do Blanketing Regulators Work?

Tank Blanketing regulators, also referred to as “Padding” or “Make-up” regulators, are controlling the pressure inside the tank. The blanketing valve is typically mounted on top of a storage tank. The piping from the blanketing gas supply is connected to the regulator inlet and the regulator outlet is piped to the tank. In most cases, a pressure sensing line runs from the tank to the regulator sensing port.

When the regulator senses a decrease in the pressure, it opens to introduce more gas into the tank until the vapor pressure in the tank reaches the desired set-point. When the pressure reaches or begins to exceed the set-point, the regulator moves to the closed position and pressure returns to the set-point.

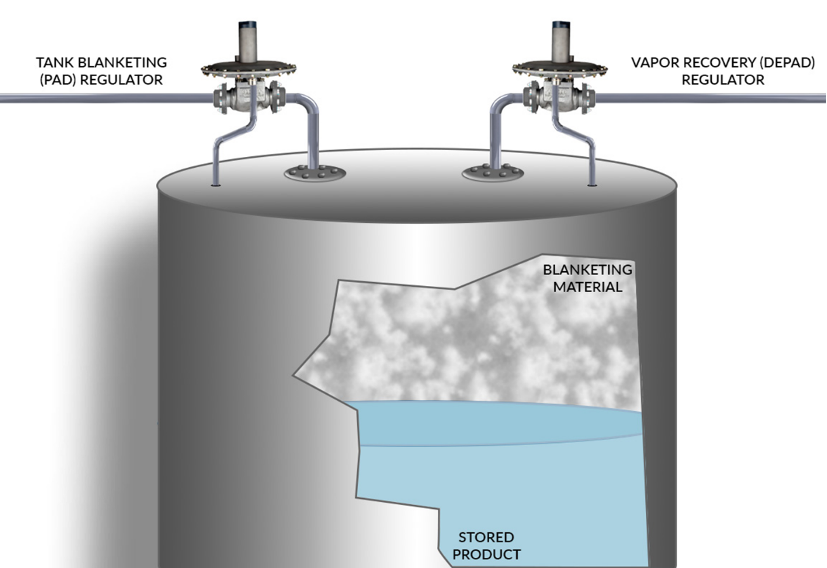

Schematic of a two-sided tank blanketing application

Controlling the Tank Blanket with a Two-Sided System: In a “two sided” blanketing system, there is a Tank Blanketing (Padding) regulator and a Vapor Recovery (De-Padding) regulator. When the vapor pressure in the tank drops below set-point, the padding regulator’s diaphragm moves its plug away from the seat, allowing the blanketing medium to flow in. When tank pressure exceeds the set-point, the de-pad regulator moves the plug away from the seat in response to higher pressure vapors, allowing excess vapors to flow out of the tank.

The padding and de-padding valves work together to maintain a constant vapor pressure in the tank. The padding valve is a pressure reducing valve (PRV) and the de-padding valve is a back pressure regulating valve (BPRV). The padding valve ensures there is sufficient pressure in the tank and the de-padding valve ensures there is not too much pressure in the tank. The set-point of the de-padding valve is slightly higher than that of the padding valve.

Why are Padding and De-Padding Regulators Needed? The volume of media in a process tank will vary due to a variety of factors including pumping media in and out, temperature changes, evaporating gases, and air or moisture entering the tank. As the volume of the media changes, the vapor space in the tank changes as well. As this fluctuation takes place, the padding regulators are automatically adjusting the gas padding to compensate and maintain a consistent pressure.

Download our Jordan Valve Tank Blanketing Reference Guide or learn more about our family of tank blanketing valves on the product page.

Contact us if you have questions about finding the right tank blanketing valve for your application.

Mark 508 Series Direct Operated Tank De-pad Regulator

Mark 508 Series Direct Operated Tank De-pad Regulator