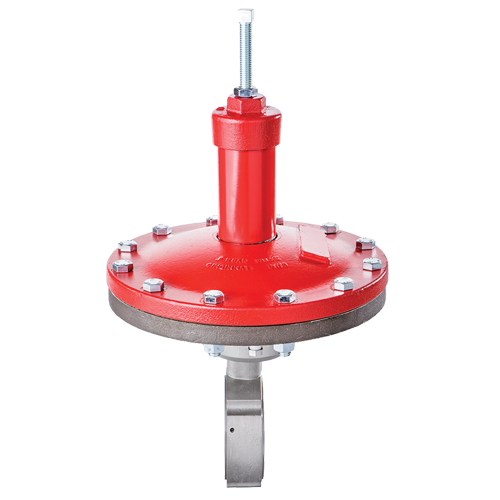

Mark 675 Series

Wafer Style, Jorlon Diaphragm

The Mark 675 Series wafer style sliding gate pressure regulator is used to regulate the downstream pressure to a predetermined setpoint. The wafer style design allows for easy installation and maintenance due to its reduced weight and sliding gate seats. The flow is straight through the valve seats and body. Direction of the disc travel is perpendicular to the flow, not opposed to the direction of the flow. The MK675 can use a wider range of its stroke to give accurate control; less offset.

- Wafer Style Body — reduces weight

- High Capacity — 6″ (DN150) provides 400 Cv (345Kv)

- Sliding Gate Trim — unique seat design for unsurpassed trim life and accuracy.

- Jorcote Seat Coating — ceramic composite for liquids, gases and especially steam. Very low friction with outstanding wear resistance and a temperature rating of up to 550°F (288°C). Steam tested to 1,000,000 cycles and still maintained Class IV leakage.

- Jorlon Diaphragm — extremely durable, virtually universally applicable up to 450°F. Tested without failure to over 1,000,000 full stroke cycles. Ideal for steam, gases and liquids. 316SST diaphragm applicable up to 550°F.

- Straight-through Flow — The flow is straight through the valve seats and body. Direction of the disc travel is perpendicular to the flow, not opposed to the direction of the flow. Thus, the flow does not unbalance the seats. The MK675 can use a wider range of its stroke to give accurate control; less offset.

- Quiet Operation — typically 5-10 dB less than conventional globe style regulators. The disc and plate are always in contact, which eliminates chattering. Straight-through flow minimizes turbulence. Multiple orifices in the plate and disc divide the flow stream into smaller flow components.

- Minimum Maintenance — The MK675 sliding gate seats require no special tools for disassembly. The seats are pre-lapped at the factory and are self-lapping while in operation ensuring a continual tight shutoff.

Sizes: 3″ – 6″ (DN80 – DN150)

Cv (Kv): up to 400 (up to 345)

Diaphragm: Jorlon, EPDM, Neoprene/Nylon, Viton, Buna-N

Setpoint: 7 – 35 psi (0,48 to 2,41 bar)

Body Material: Carbon Bar, Carbon Steel, Stainless Steel Bar, Stainless Steel

Options: Closing Cap, Handwheel (Range Options), Bleed Port, Stainless Bolting, Clean for Oxygen or Oil-Free Service

Sliding Gate Valves

You will notice something different in many Jordan valves … the sliding gate seat. A remarkably simple concept that offers superior performance and benefits not found in traditional rising stem and rotary valves.

CRN Number

Mark 695: 3″ – 6″

ATEX Certified

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.