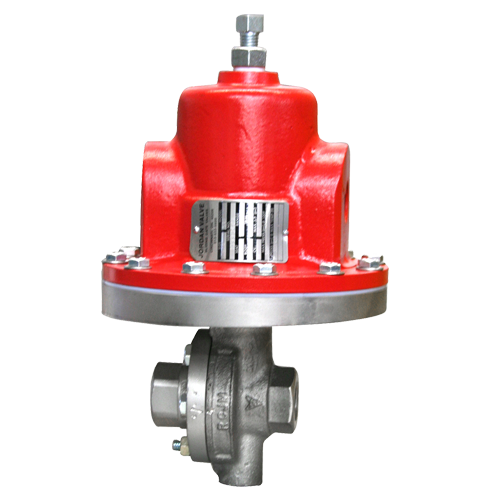

Mark 53/54 Series

Differential, Jorlon Diaphragm

The Mark 53 and 54 Series transform challenging differential pressure control into reliable, repeatable operation. By maintaining a precise pressure differential between inlet and signal pressure, these valves enable sophisticated process control strategies – from maintaining consistent pressure drops across filters and strainers to managing complex reactor pressure profiles. When your process depends on maintaining exact pressure relationships, not just absolute pressures, these valves deliver the control intelligence you need.

The Mark 53 provides robust differential pressure control for standard applications, while the Mark 54's larger diaphragm minimizes pressure offset for ultra-precise control. This reduced offset means your actual operating pressure stays closer to setpoint across varying flow conditions – critical for sensitive processes where even minor pressure deviations impact product quality or yield. Both deliver identical flow capacity, so you're choosing precision level, not compromising throughput.

The Mark 54's capability for both differential and remote adjustment opens doors to sophisticated control schemes. Operators can fine-tune pressure relationships from the control room, adapting to changing process conditions without entering hazardous areas. The negative differential option enables unique applications like vacuum breaker control or maintaining precise suction pressures – capabilities that typically require complex instrumented systems.

Application Benefits:

- Protect critical equipment by maintaining exact pressure drops across filters, preventing breakthrough

- Optimize reaction kinetics with precise pressure differential control in multi-stage processes

- Enable remote optimization without manual field adjustments in hazardous locations

- Reduce energy consumption by maintaining optimal pressure relationships across system components

- Simplify complex control loops by handling differential control mechanically rather than through instrumentation

- Extend filter life through consistent differential pressure monitoring and control

The Mark 53/54 Series brings intelligent pressure control to applications where simple upstream or downstream regulation isn’t enough – delivering the sophisticated control your complex processes demand.

Sizes: MK53″ 1/4″ – 2″ (DN8 – DN50); MK54: 1/4″ – 3/4″ (DN8 – DN20)

Cv (Kv): up to 30 (up to 25,8)

Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

Setpoint: MK53: 0.5 – 150 psi (0,03 to 10,3 bar); MK 54: 0.5 to 170 psi (0,03 to 11,7 bar)

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Options: Double Diaphragm, Flow through Dome, and Handwheel

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

- EC Declaration of Conformity/PED:

Mark 53: 1-1/4″ -2″

Mark 54: 1/4″ – 3/4″ - CRN Number

Mark 53: 1/4″ – 2″

Mark 54: 1/4″ – 3/4″ - ATEX Certified

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.