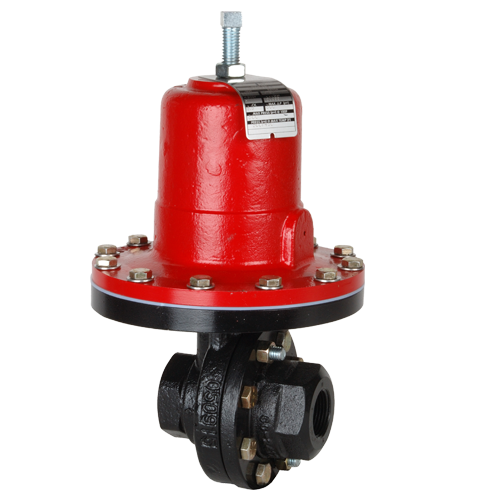

Mark 55 Series

Upstream Vacuum, Jorlon Diaphragm

The Mark 55 Series delivers the precise vacuum control essential for sensitive processes where even minor fluctuations can ruin product batches or damage equipment. Whether you're managing evaporator efficiency, ensuring consistent product quality in vacuum cookers, maintaining precise conditions in altitude testing chambers, or protecting delicate dairy operations, this valve maintains your exact vacuum setpoint with tight shutoff that prevents vacuum loss during idle periods. Your processes run at optimal efficiency while eliminating the energy waste and equipment wear caused by vacuum instability.

Sliding Gate Technology Optimized for Vacuum Service The straight-through flow design eliminates the turbulence that causes noise and instability in traditional vacuum regulators – critical when maintaining precise vacuum levels. The short stroke provides lightning-fast response to vacuum fluctuations, preventing the pressure spikes that can damage sensitive equipment or disrupt delicate processes. When process requirements change, easily interchangeable Cv’s let you optimize performance without valve replacement, while the tight shutoff capability ensures your vacuum systems maintain efficiency during standby periods.

Built for Reliability in Demanding Vacuum Applications The all-metal construction eliminates the weak points that plague vacuum systems. With no gaskets, o-rings, or elastomers to degrade under vacuum conditions, you eliminate the most common causes of vacuum leaks and performance degradation. This robust design means consistent performance year after year, with no gradual deterioration from elastomer hardening or outgassing that contaminates sensitive processes.

Operational Excellence Through Simplicity The compact design fits easily into crowded vacuum manifolds, while simple construction means your maintenance team can service it quickly without specialized training. Fast installation reduces project timelines and minimizes system downtime during retrofits or expansions.

Benefits:

- Protect product quality with stable vacuum control in sensitive processes

- Reduce energy costs through tight shutoff and consistent vacuum levels

- Minimize unplanned downtime with no elastomers to fail unexpectedly

- Extend equipment life by preventing vacuum instability and pressure spikes

- Simplify maintenance with straightforward design and no wearing soft goods

The Mark 55 Series brings Jordan’s proven sliding gate reliability to vacuum applications where precision matters most.

Sizes: 1/4″ – 2″ (DN8 – DN50)

Cv (Kv) up to 30 (up to 25,8)

Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

Vacuum Range: 1″ Hg to 25″ Hg vacuum (0,035 to 0,886 kg/cm2)

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

- EC Declaration of Conformity/PED:

Mark 55: 1-1/4″ – 2″ - CRN Number

Mark 55: 1/4″ – 2″ - ATEX Certified

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.