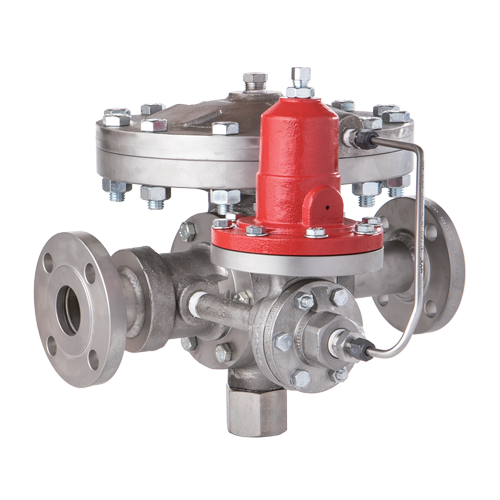

Mark 57 Series

Pilot-Operated, Superior Accuracy

The Mark 57 Series pilot-operated back pressure regulator is designed to accurately control pressure to 90% of its rated flow capacity with only a small deviation from setpoint, providing accuracy that approaches that of controller-operated valves and should be considered on most critical applications. This versatile regulator features Jordan Valve's proprietary sliding gate seat technology, which provides straight-through flow for reduced turbulence, quiet operation, fast response, and tight shutoff. Available in sizes ranging from 1/2" to 6" (DN15 to DN150) with Cv values up to 395 (Kv up to 340), the Mark 57 can handle a wide variety of applications including steam, air, gas, liquids, and chemicals. The regulator features a stainless steel diaphragm and offers setpoint ranges from 10 to 185 psi (0.7 to 12.8 bar), with high turn-down ratios up to 50:1. Body materials include ductile iron, carbon steel, stainless steel, and cast iron, with various end connection options including threaded, flanged, socket weld, and butt weld configurations. The Mark 57 carries both EC Declaration of Conformity/PED certification for sizes 1-1/4" to 6" and CRN (Canadian Registration Number) approval for the full size range from 1/2" to 6".

- Exceptional Control Accuracy – Maintains pressure control to 90% of rated flow capacity with minimal deviation from setpoint, reducing process variability and eliminating the need for frequent manual adjustments

- Simplified Maintenance Design – Jordan Valve’s sliding gate seats lift out easily without special tools or pressed/screwed components, dramatically reducing downtime and maintenance complexity

- Extended Service Life – Self-lapping sliding gate seats actually improve over time rather than wearing out, minimizing replacement frequency and reducing spare parts inventory

- Versatile Application Range – Handles steam, air, gas, liquids, and chemicals in a single valve design, simplifying specification and reducing the variety of valve types needed in inventory

- High Turn-Down Capability – Achieves up to 50:1 turn-down ratios, allowing a single valve to handle wide flow variations without requiring multiple valve sizes

- Reduced Noise Levels – Straight-through flow design with sliding gate technology operates 5-10 dB quieter than conventional globe valves, improving workplace safety and comfort

- Interchangeable Trim Options – Cv values can be changed in the field without replacing the entire valve body, providing flexibility for changing process conditions

- Fast Response Time – Short stroke design of sliding gate mechanism provides rapid response to process changes, improving overall system stability

- Reliable Tight Shutoff – Metal-to-metal sliding gate contact ensures consistent Class IV shutoff throughout the valve’s service life, preventing costly product loss or energy waste

- Wide Operating Range – Available in sizes from 1/2″ to 6″ with setpoints from 10 to 185 psi, covering most industrial applications with a standardized valve series

Sizes: 1/2″ – 6″ (DN15 – DN150)

Cv (Kv): up to 395 (up to 340)

Diaphragm: Stainless Steel

Setpoint: 10 to 185 psi (0,7 to 12,8 bar)

Body Material: Ductile Iron, Carbon Steel, Stainless Steel, Cast Iron

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

- EC Declaration of Conformity/PED:

Mark 57: 1-1/4″ – 6″ - CRN (Canadian Registration Number)

Mark 57: 1/2″ – 6″

Your List

Email List

Get A Quote

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.