How to Choose a Reliable Steam Pressure Regulator

Ensuring safe and efficient steam pressure levels is critical for the smooth operation of industrial processes and plant systems. Operating at optimal pressure not only protects equipment but also improves overall system performance. This is where steam pressure regulators, also known as steam pressure reducing valves, play a key role.

In this post, we’ll look at what a steam pressure regulator is and the key considerations to keep in mind when selecting one, so you can prevent system failures and keep your operations running reliably.

What Is a Steam Pressure Regulator?

A steam pressure regulator is a control valve that automatically reduces and stabilizes the pressure of steam flowing through a system. It works by maintaining a preset downstream pressure while allowing steam to flow freely. This ensures the system operates safely and consistently under varying load conditions.

Key Considerations for Selecting the Right Steam Pressure Regulator

When selecting a steam pressure reducing valve, it is essential to consider factors such as:

- Determine Your Pressure Requirements:

Identify the inlet and outlet pressure range that your steam system needs. Since every system operates under different pressure conditions, it’s essential to select a regulator that can reliably perform within both normal operating conditions and peak demand scenarios.

- Assess Flow Capacity (Capacity):

Capacity indicates the maximum amount of steam a regulator can manage. Choosing a regulator with the right capacity is vital to ensure it can handle your system’s steam flow demands, keeping operations steady, safe, and efficient.

| Valve Size | Approximate Cv | Maximum Flow (lb/hr) |

| 1 inch | 10 | 2500 |

| 2 inches | 40 | 10000 |

| 3 inches | 90 | 22500 |

| 4 inches | 150 | 37500 |

- Material Selection Matters:

Steam systems operate under extreme temperatures and pressures. Regulators made from materials like stainless steel and carbon steel deliver durability, reliability, and long-term performance in demanding steam applications.

- Accuracy and Reliability:

Precise pressure control is essential to ensure both safety and efficiency in steam systems. To avoid unexpected downtime or safety risks, it’s important to select regulators known for their accuracy and consistent performance in demanding steam environments.

- Factor in Maintenance and Repair Requirements:

Ease of maintenance is another important consideration. A design that allows for quick, hassle-free maintenance not only reduces downtime but also boosts productivity and helps cut long-term operating costs.

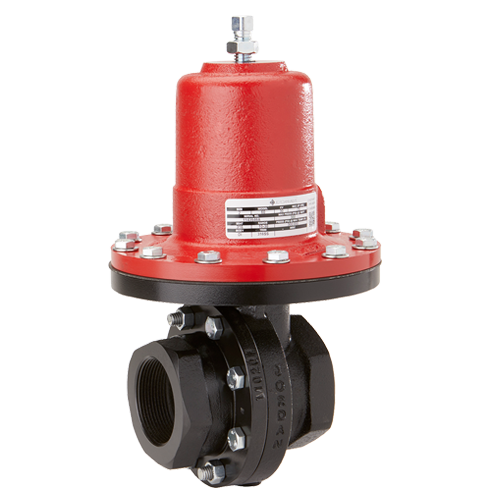

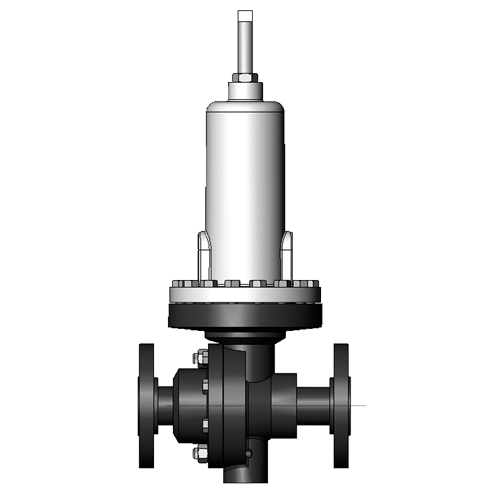

Delivering Long-Term Reliability and Robustness

While these considerations are essential when selecting a steam pressure regulating valve, long-term reliability ultimately comes down to proven design and performance. For example, Jordan Valve steam pressure regulators are engineered with a sliding gate seat design that reduces the risk of frequent failures and delivers consistent results under demanding steam conditions. This makes them a trusted choice for industries that prioritize safety, efficiency, and dependable operation.

Conclusion

Selecting the right steam pressure regulator requires careful consideration of pressure range, capacity, materials, accuracy, and maintenance needs. By focusing on these key factors, you can ensure long-term reliability, safety, and efficiency in your steam systems. Get in touch with our team, and we will help you find the right regulator for your application!

Mark 60 Series

Mark 60 Series  Mark 601/602 Series

Mark 601/602 Series  Mark 60HP Series

Mark 60HP Series