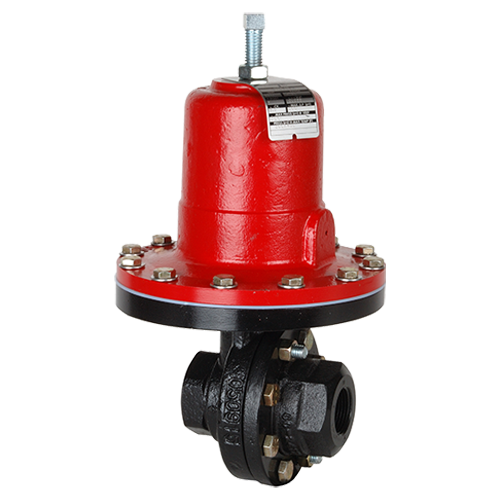

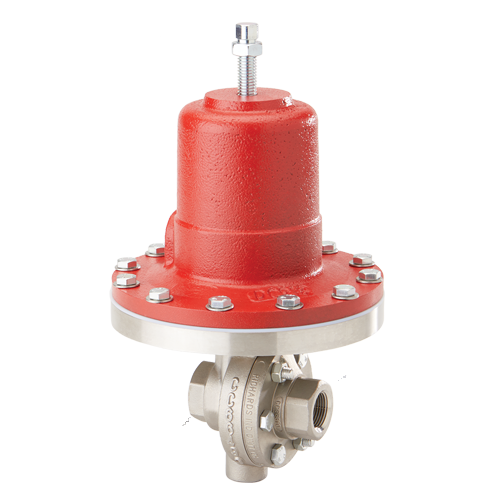

Mark 501/502 Series

High Flow Back Pressure Regulator; Sliding Gate; 1-1/2″ – 2″ (DN40 – DN50)

Higher Steam Flow Without Upsizing – Cut Costs, Boost Efficiency, and Reduce Maintenance

When your steam application demands higher flow capacity, but jumping to a larger line size isn’t in the budget—or the plant layout—you need a smarter solution. The Mark 501 and Mark 502 Series back pressure regulators deliver high and ultra-high flow performance without the added cost, space, and complexity of upsizing.

The Mark 501 handles flows up to Cv 50 (Kv 43), and the Mark 502 pushes that even further to Cv 70 (Kv 60)—giving you more throughput, more efficiency, and more control with the same line size.

And thanks to precision-engineered sliding gate seats, these regulators fight the internal build-up that often plagues high-flow steam systems. That means fewer shutdowns, less maintenance, and more uptime—so your operation keeps running hot, clean, and efficient.

Maximize Uptime, Minimize Costs The sliding gate’s shorter stroke means faster response to pressure changes, preventing costly process upsets. Its compact design reduces installation costs, while minimal surface exposure dramatically cuts fouling and build-up – keeping your process running when traditional regulators would need shutdown.

Extend Equipment Life Straight-through flow eliminates the erosion and turbulence that destroy conventional regulators. You’ll see years of additional service life, lower noise levels for a safer workplace, and improved rangeability that lets one valve handle varying conditions – reducing your spare parts inventory.

Simplify Maintenance When service is needed, interchangeable seats adapt to changing conditions without valve replacement. Fewer spare parts mean lower inventory costs and less downtime risk. The self-cleaning design often turns major maintenance into simple inspections, while the absence of gaskets and o-rings eliminates common leak points and safety concerns.

Bottom Line Impact:

- Reduced unplanned downtime through reliable pressure control

- Lower total ownership costs via extended life and simplified maintenance

- Better process stability for improved quality and yield

- Enhanced safety through reduced noise and fewer failure points

This isn’t just advanced technology – it’s measurable operational improvement that protects your investment and your team.

Sizes: 1-1/2″ – 2″ (DN40 – DN50)

Cv (Kv): up to 70 (up to 60)

Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

Setpoint: 0.5 to 150 psi (0,03 to 10,3 bar)

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Sliding Gate Valves

You will notice something different in many Jordan valves … the sliding gate seat. A remarkably simple concept that offers superior performance and benefits not found in traditional rising stem and rotary valves.

CRN Number

Mark 501/502: 1-1/2″ & 2″

ATEX Certified

Your List

Email List

Get A Quote

Related Products

Mark 50 Series

Self-Operated Sliding Gate Back Pressure Regulator; Quick Ship Available

1/4" - 4", up to 200 Cv

Mark 51 Series

Large diaphragm, 1/4" - 3/4" size range

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.