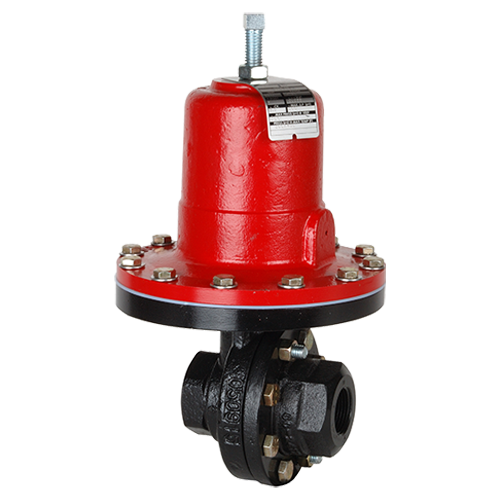

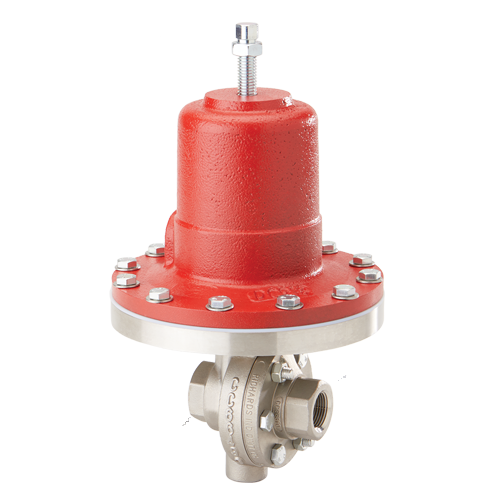

Mark 50 Series

Self-Operated Sliding Gate Back Pressure Regulator; Quick Ship Available 1/4" - 4", up to 200 Cv

The Mark 50 Series is built for versatility, handling steam, water, oil, gas, air, and chemicals with ease. Featuring a high-capacity sliding gate trim, it delivers precise, rapid pressure regulation to prevent dangerous over-pressures across a wide range of applications.

- Sizing: 1/4″ – 4″ (DN8 – DN100)

- Cv (Kv): up to 200 (up to 172)

Need it fast? We offer quick ship options to get your system running without delay.

- Unmatched Trim Life & Accuracy — Sliding Gate Trim: The unique seat design delivers exceptional durability and precise control, reducing the need for frequent maintenance and ensuring accurate pressure regulation over time.

- Rapid Pressure Adjustment — Fast Response: The short stroke of the sliding gate enables quick reaction to changes in process conditions, minimizing pressure offsets and improving system stability.

- Efficient, Uninterrupted Flow — Straight-Through Flow: With the flow running directly through the valve, and the disc moving perpendicular to it, pressure regulation is smoother, and seat imbalance is eliminated, leading to enhanced operational efficiency.

- Quieter Operation — Noise Reduction: The innovative Sliding Gate seats reduce noise compared to traditional regulators. The disc and plate remain in constant contact, preventing chattering, while the straight-through flow minimizes turbulence and further reduces noise.

- Easy Maintenance — Low-Cost, Low-Maintenance: The Mark 50’s sliding gate seats require no special tools for disassembly. Pre-lapped at the factory, the seats self-lap during operation to maintain a tight shutoff, significantly reducing downtime and service costs.

- Sizes: 1/4″ – 4″ (DN8 – DN100)

- Cv (Kv): up to 200 (up to 172)

- Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

- Setpoint: MK50: 0.5 to 150 psi (0,03 to 10,3 bar); MK50HP: 75 to 450 psi (5,2 to 31,0 bar)

- Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel, Cast Iron

- End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Sliding Gate Valves

You will notice something different in many Jordan valves … the sliding gate seat. A remarkably simple concept that offers superior performance and benefits not found in traditional rising stem and rotary valves.

How Choosing a Sliding Gate Valve Could Save Money in Steam Applications

Read about sliding gate valves, how they work, why they outperform in steam service, and read a case study describing how installing Jordan sliding gate control valves tightened a customer’s dryer temperatures and helped increase throughput.

- EC Declaration of Conformity/PED:

Mark 50: 1-1/4″ – 4″ - CRN (Canadian Registration Number)

Mark 50: 1/4″ – 4″

Mark 50QC: 1/4″ – 2″ - UL Listed

- ATEX Certified

The Mark 50 Series is available for Quick Ship – ships within 5 business days

- 1-week (5 business days) lead times on core Mark 50 Regulators: 1/2″ – 2″ sizes with NPT connections in SS/DI/WCB/BRZ materials

- 1-week (5 business days) lead times on core Mark 50 Regulators: 1/2″ – 2″ sizes with 150# or 300# connections in SS/WCB materials

- Cv Ranges: Standard (largest) Cv on given line size and 1 reduction (MK50 brochure, page 4)

- Standard spring housing / Jorlon / Jorcote seats

- Standard documentation requested at time of order

- Shipping method and complete shipping address provided at time of order

- Quantities: 1 or 2 pieces but contact us for larger quantity needs

1/4″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

1/4″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

3/8″ Mark 50 Series Carbon and Stainless Steel with FNPT Ends

3/8″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Ends

1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Ends

1/2″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

3/4″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

3/4″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

3/4″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

3/4″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

3/4″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1/2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

1″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1-1/4″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1-1/4″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1-1/4″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

1-1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

1-1/2″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

1-1/2″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

1-1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

1-1/2″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

1-1/2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

2″ Mark 50 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

2″ Mark 50 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

2″ Mark 50 Series Carbon & Stainless Steel with FNPT Ends

2″ Mark 50 Series Ductile Iron & Bronze with Welded 300# Flanged Ends

2″ Mark 50 Series Ductile Iron & Bronze with Welded 150# Flanged Ends

2″ Mark 50 Series Ductile Iron & Bronze with FNPT Ends

2-1/2″ Mark 50 Series All Materials with Integral 300# Flanged Ends

2-1/2″ Mark 50 Series All Materials with Intergral 150# Flanged Ends

3″ Mark 50 Series All Materials with Integral 300# Flanged Ends

3″ Mark 50 Series All Materials with Integral 150# Flanged Ends

4″ Mark 50 Series All Materials with Integral 300# Flanged Ends

4″ Mark 50 Series All Materials with Integral 150# Flanged Ends

The Mark 50 Series is available for Quick Ship – ships within 5 business days

Scope

- 1/2″ – 2″ (DN15 – DN50) sizes

- NPT ends

- Ductile Iron, Carbon Steel, Stainless Steel and Bronze materials

- Jorlon and Stainless Steel diaphragm

- Jorcote 303 + 316 seat material

- Standard spring housing (DI)

- 2 per order per size max quantity

- Standard docs requested at the time of order (C-C, final test certificate, standard MTR)

Your List

Email List

Get A Quote

FAQs

1. Should the seat on the Mark 50 back pressure regulator be opened or closed when the valve is not operating?

On a Mark 50 and any size back pressure regulator that has the sliding gate seat, the valve will be stroked down and the seat will be closed when it’s not opening.

Learn more about adjusting the seat on your Mark 50 back pressure regulator here.

2. How can I disassemble and repair my Mark 50 back pressure regulator?

To learn how to disassemble and repair the Mark 50 series back pressure regulator, watch our instructional video.

Visit our resource page for more product installation and maintenance videos.

How will I know if I have the correct flow direction?

There will be an arrow cast into the side of the body of the Mark 50 series back pressure regulator, this arrow has to always be pointed in the direction that is going with the flow, not against it.

Watch our Flow Direction help video for more information.

Related Products

Mark 501/502 Series

High Flow Back Pressure Regulator; Sliding Gate; 1-1/2″ – 2″ (DN40 – DN50)

Mark 51 Series

Large diaphragm, 1/4" - 3/4" size range

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.