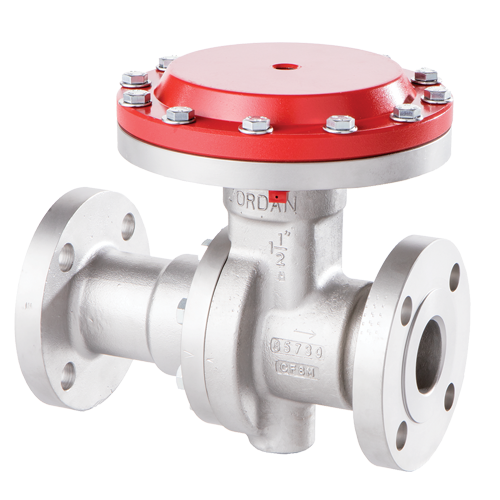

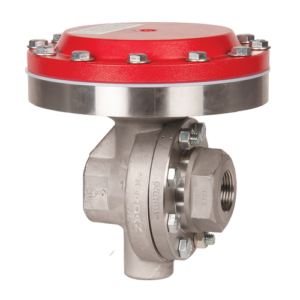

Mark 56/560 Series

Dome Loaded, High Accuracy

The Mark 56/560 Series dome loaded back pressure regulator revolutionizes back pressure control by eliminating mechanical springs in favor of precise air loading. This means you can adjust setpoints on-the-fly to match changing process conditions – no more manual spring changes, no more compromise setpoints, no more shutdowns for pressure adjustments. Whether optimizing batch processes, responding to seasonal demand changes, or fine-tuning system performance, you now have complete control at your fingertips. Configure control exactly how your operation needs it. Couple with an I/P transducer for seamless integration with your DCS or PLC, enabling remote setpoint changes and automated pressure profiles. For local control, pair with a Mark 12 loading station or LowFlow JR regulator for precise manual adjustment. This flexibility of this dome loaded back pressure regulator means operators can optimize pressure from the control room during normal operation, while maintenance staff retain local control capability for commissioning and troubleshooting.

Universal Service Reliability One valve design handles your entire spectrum of process fluids – high-temperature steam, compressed air systems, natural gas distribution, liquid chemicals, or corrosive services. The all-metal construction (2″ and under) eliminates elastomer degradation concerns, while the sliding gate design delivers consistent performance across all media types. This versatility simplifies spare parts inventory and maintenance training while ensuring reliable operation in any service.

Performance That Responds to Your Process The sliding gate’s short stroke and straight-through flow path deliver immediate response to both process changes and setpoint adjustments. Reduced turbulence means quieter operation and less erosion, while easily interchangeable Cv’s let you optimize for changing flow requirements. Tight shutoff prevents waste and maintains system efficiency during no-flow conditions.

Benefits:

- Eliminate downtime for spring changes or pressure adjustments

- Enable automated pressure control strategies through DCS integration

- Reduce inventory costs with one valve style for multiple services

- Improve process flexibility with instant setpoint changes

- Enhance safety through remote adjustment capability in hazardous areas

- Optimize efficiency by matching pressure to real-time process demands

The Mark 56/560 Series brings intelligent, adaptable pressure control to operations that demand flexibility without sacrificing reliability.

Sizes: 1/2″ – 6″ (DN15 – DN150)

Cv (Kv): up to 395 (up to 340)

Diaphragm: Jorlon, Stainless Steel, Buna-N, Viton

Setpoint: up to body ratings

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel, Cast Iron

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

- CRN Number

Mark 56: 1/2″ – 6″ - ATEX Certified

Notice Regarding 3D STEP Files:

The 3D STEP files provided on this website contain proprietary information and are intended solely for use by authorized customers. These files must not be used, distributed, or repurposed by third-party vendors for promotional, marketing, or any other non-customer-related activities. Unauthorized use may violate intellectual property protections and confidentiality agreements.

1/2″ Mark 56 Series Bronze & Ductile Iron with BSPP Ends

1/2″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

1/2″ Mark 56 Series Bronze & Ductile Iron with 300# Flanged Ends

1/2″ Mark 56 Series Bronze & Ductile Iron with 150# Flanged Ends

1/2″ Mark 56 Series Bronze & Ductile Iron with FNPT Ends

1/2″ Mark 56 Series Carbon & Stainless Steel with BSPP Ends

1/2″ Mark 56 Series Carbon & Stainless Steel with BSPT Ends

1/2″ Mark 56 Series Carbon & Stainless Steel with 300# Flanged Ends

1/2″ Mark 56 Series Carbon & Stainless Steel with 150# Flanged Ends

1/2″ Mark 56 Series Carbon & Stainless Steel with FNPT Ends

1/2″ Mark 56 Series Carbon & Stainless Steel with Socket Weld Ends

3/4″ Mark 56 Series Bronze & Ductile Iron with BSPP Ends

3/4″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

3/4″ Mark 56 Series Bronze & Ductile Iron with 300# Flanged Ends

3/4″ Mark 56 Series Bronze & Ductile Iron with 150# Flanged Ends

3/4″ Mark 56 Series Bronze & Ductile Iron with FNPT Ends

3/4″ Mark 56 Series Carbon & Stainless Steel with BSPP Ends

3/4″ Mark 56 Series Carbon & Stainless Steel with BSPT Ends

3/4″ Mark 56 Series Carbon & Stainless Steel with 300# Flanged Ends

3/4″ Mark 56 Series Carbon & Stainless Steel with 150# Flanged Ends

3/4″ Mark 56 Series Carbon & Stainless Steel with FNPT Ends

3/4″ Mark 56 Series Carbon & Stainless Steel with Socket Weld Ends

1″ Mark 56 Series Bronze & Ductile Iron with BSPP Ends

1″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

1″ Mark 56 Series Bronze & Ductile Iron with 300# Flanged Ends

1″ Mark 56 Series Bronze & Ductile Iron with 150# Flanged Ends

1″ Mark 56 Series Bronze & Ductile Iron with FNPT Ends

1″ Mark 56 Series Carbon & Stainless Steel with BSPP Ends

1″ Mark 56 Series Carbon & Stainless Steel with BSPT Ends

1″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

1″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

1″ Mark 56 Series Carbon & Stainless Steel with BSPT Ends

1″ Mark 56 Series Carbon & Stainless Steel with Socket Weld Ends

1-1/4″ Mark 56 Series Bronze & Ductile Iron with BSPP Ends

1-1/4″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

1-1/4″ Mark 56 Series Bronze & Ductile Iron with 300# Flanged Ends

1-1/4″ Mark 56 Series Bronze & Ductile Iron with 150# Flanged Ends

1-1/4″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

1-1/2″ Mark 56 Series Bronze & Ductile Iron with BSPP Ends

1-1/2″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

1-1/2″ Mark 56 Series Bronze & Ductile Iron with 300# Flanged Ends

1-1/2″ Mark 56 Series Bronze & Ductile Iron with 150# Flanged Ends

1-1/2″ Mark 56 Series Bronze & Ductile Iron with FNPT Ends

1-1/2″ Mark 56 Series Carbon & Stainless Steel with BSPP Ends

1-1/2″ Mark 56 Series Carbon & Stainless Steel with BSPT Ends

1-1/2″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

1-1/2″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

1-1/2″ Mark 56 Series Carbon & Stainless Steel with FNPT Ends

1-1/2″ Mark 56 Series Carbon & Stainless Steel with Socket Weld Ends

2″ Mark 56 Series Bronze & Ductile Iron with BSPP Ends

2″ Mark 56 Series Bronze & Ductile Iron with BSPT Ends

2″ Mark 56 Series Bronze & Ductile Iron with 300# Flanged Ends

2″ Mark 56 Series Bronze & Ductile Iron with 150# Flanged Ends

2″ Mark 56 Series Bronze & Ductile Iron with FNPT Ends

2″ Mark 56 Series Carbon & Stainless Steel with BSPP Ends

2″ Mark 56 Series Carbon & Stainless Steel with BSPT Ends

2″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

2″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

2″ Mark 56 Series Carbon & Stainless Steel with FNPT Ends

2″ Mark 56 Series Carbon & Stainless Steel with Socket Weld Ends

2-1/2″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

2-1/2″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

3″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

3″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

4″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

4″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

6″ Mark 56 Series Carbon & Stainless Steel with Integral 300# Flanged Ends

6″ Mark 56 Series Carbon & Stainless Steel with Integral 150# Flanged Ends

Your List

Email List

Get A Quote

Explore our comprehensive range of Back Pressure Regulators engineered for diverse industrial applications.

Related Products

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.