Mark 75HW Series

Wafer Style, Hand Operated, Precise Adjustment

The Mark 75HW is a manually operated, sliding gate control valve. The hand wheel operator allows the user to manually position the valve for optimum flow and lock in place. The Mark 75HW features a "T" slot design connection to the disc. This connections allows for quick and easy reversing of functions. The valve can go from reverse acting to direct acting (or vice versa).

- Easy installation between flanges with wafer body

- High flow rates

- Self cleaning, self-lapping seats

- Reduced noise compared to conventional globe/cage valves

- More resistant to cavitation / flashing with straight through wafer design

Sizes: 1″ – 2″ (DN25 – DN50)

Body Material: 316 Stainless Steel, Carbon Steel

Seat Materials: Jorcote/316SS standard

Cv (Kv): up to 72 (up to 62)

Turndown Ratio Capability: 100:1

Max Inlet Pressure: 150 psi (10 bar)

Sliding Gate Valves

You will notice something different in many Jordan valves … the sliding gate seat. A remarkably simple concept that offers superior performance and benefits not found in traditional rising stem and rotary valves.

ATEX Certified

Your List

Email List

Get A Quote

Related Products

Mark 75 Series

Wafer Style, Motor Operated, Very Precise

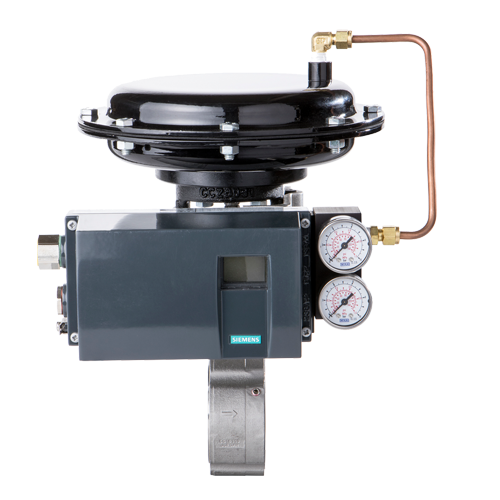

Mark 75MV Series

Wafer Style, Motor Operated Control Valve; Sliding Gate; 1″ - 8″ (DN25 - DN200)

Mark 75PTP Series

Piston Operated with Smart Positioner

Explore our comprehensive range of Wafer Style Control Valves engineered for diverse industrial applications.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.