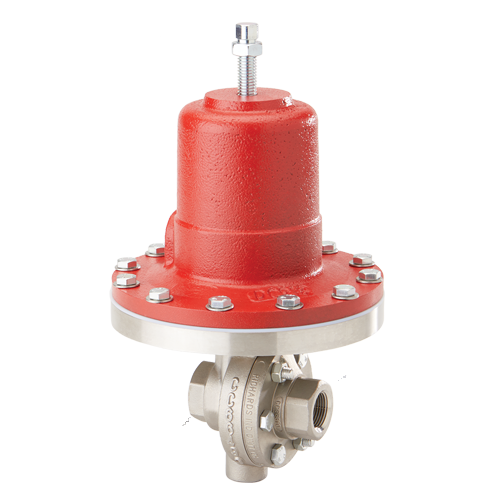

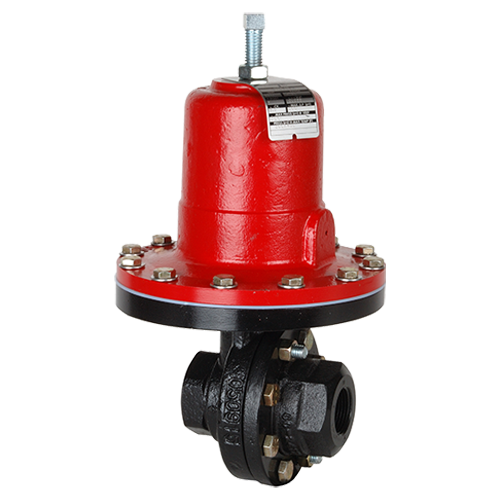

Mark 51 Series

Large diaphragm, 1/4" - 3/4" size range

The Mark 51 Series high temperature back pressure regulator delivers reliable back pressure regulation across your entire facility's fluid systems – from high-temperature steam lines to corrosive chemical processes. Whether you're managing water utilities, oil circulation systems, compressed air networks, or specialty gas applications, one valve design handles them all. This versatility means simplified spare parts inventory, consistent maintenance procedures across different services, and reduced training requirements for your team.

Superior Flow Capacity with Precision Control The Mark 51’s excellent flow capacity ensures you won’t sacrifice throughput for control accuracy. The sliding gate trim technology provides the rapid response needed to prevent costly over-pressure events that could damage upstream equipment or trigger safety shutdowns. Unlike traditional globe-style regulators that struggle with varying flow conditions, the Mark 51 maintains precise control whether you’re at 10% or 90% of capacity.

Enhanced Sensitivity for Critical Process Control The larger diaphragm design delivers exceptional sensitivity to pressure changes, catching and correcting minor fluctuations before they become process upsets. This enhanced responsiveness means tighter pressure control bands, more consistent product quality, and reduced wear on upstream equipment from pressure cycling. In applications where even small pressure variations matter – such as reactor feeds or precision dosing systems – this sensitivity translates directly to improved process performance.

Benefits:

- Reduced equipment damage from over-pressure protection across diverse services

- Lower inventory costs with one valve style for multiple applications

- Improved process stability through superior sensitivity and fast response

- Extended equipment life upstream due to consistent pressure control

- Simplified maintenance with common procedures across all fluid types

The Mark 51 Series combines Jordan’s proven sliding gate technology with enhanced sensitivity, delivering the versatile, reliable pressure control your complex processes demand.

Sizes: 1/4″ – 3/4″ (DN8 – DN20)

Cv (Kv): up to 4.4 (up to 3,8)

Diaphragm: Stainless Steel, Elastomer

Setpoint: 0.5 to 170 psi (0,03 to 11,7 bar)

Body Material: Ductile Iron, Bronze, Carbon Steel, Stainless Steel

End Connection: Threaded, Flanged, Socket Weld, Butt Weld

Benefits of the Sliding Gate

Read on to learn the benefits of owning sliding gate regulators and control valves.

Sliding Gate Infographic

Download this infographic on the benefits of the sliding gate in regulators and control valves.

Sliding Gate Valve Overview

Watch this video for an overview of Sliding Gate Pressure Regulators and Control Valves

Sliding Gate Videos

Explore our collection of videos dedicated to sliding gate valves, particularly designed for efficient operation in steam and high temperature applications.

CRN Number

Mark 51 Series: 1/4″ – 3/4″

ATEX Certified

Your List

Email List

Get A Quote

Explore our comprehensive range of Back Pressure Regulators engineered for diverse industrial applications.

Related Products

Mark 50 Series

Self-Operated Sliding Gate Back Pressure Regulator; Quick Ship Available

1/4" - 4", up to 200 Cv

Mark 501/502 Series

High Flow Back Pressure Regulator; Sliding Gate; 1-1/2″ – 2″ (DN40 – DN50)

Y-Type Strainers

Line Strainers

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.