Steam Valve for Tire Curing Press

Jordan Valve sliding gate technology outperforms in challenging tire curing process

Curing is an important step in tire manufacturing, where the green tire is formed to the proper shape and the material is converted to its final properties for optimum performance. The tire curing press uses high steam pressure that requires valves with precision control and robust design to handle extreme process conditions.

Why Jordan sliding gate valves are a good solution

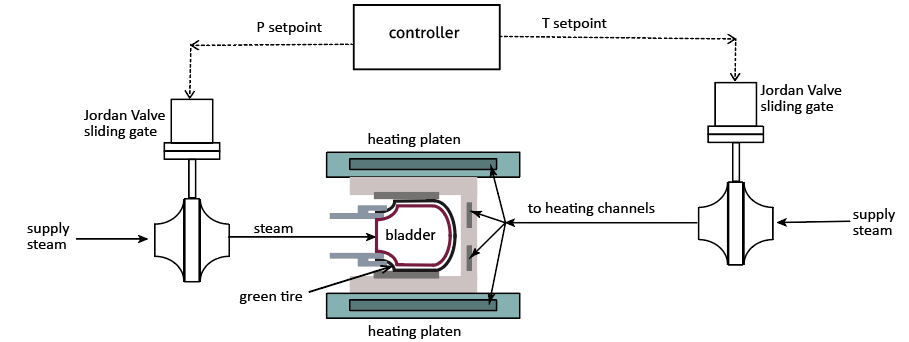

Jordan Valve sliding gate regulators and control valves have proven to be exceptional solutions in tire curing press applications. Steam pressure control to the bladder during tire shaping and steam control of the platen temperature for curing are two of those specific applications. The unique characteristics of the sliding gate technology provide several advantages over globe style valves in these processes.

- The sliding gate design lasts longer in steam service.

- straight-thru flow reduces turbulence and noise.

- Self-cleaning design requires less maintenance.

- Valve rebuilding take only a few minutes.

A schematic of a tire press is shown below. One Jordan sliding gate valve is controlling the steam to the bladder for shaping the green tire material. A second valve is used to control the steam that maintains the temperature of the platens.

Sliding gate valves stand up to demanding steam service

Tire forming applications tend to damage the internal workings of the valve which fill the forming bladders with 240 – 250psi steam. This filling process starts out slowly and then rapidly increases. Once the bladder is filled, the valves must hold a set pressure, even under possible vacuum conditions, for a specified number of minutes while the tire cures. This process is repeated every 10 – 15 minutes, 24 hours a day. In addition to the demanding fill rate and potential vacuum conditions, many tire manufacturing plants have very dirty steam systems. The combination of these extreme conditions can cause most “ordinary” valves to fail in a matter of months.

Jordan Valve sliding gate seats, with their advanced Jorcote coating, have demonstrated minimal wear for over one million cycles in high-pressure steam service. The sliding gate opens, exposing multiple passages simultaneously. The steam travels straight through multiple openings, reducing the damaging exposure of steam on each surface. This reduces the possibility of wire draw which often occurs in traditional steam valve designs.

The disc and plate are lapped to light band flatness and have a slight overlap of the openings to give the sliding gate seat valves a shut-off rating of ANSI Class IV. The seat overlap in the sliding gate design is a critical advantage. Any damage to the leading edge of the valve seat due to erosive nature of steam will be covered when the sliding gate closes, ensuring full shut-off.

The short stem stroke minimizes wear and packing leakage, while increasing response speed. This is particularly useful in the rapid cycling environment of tire forming applications.

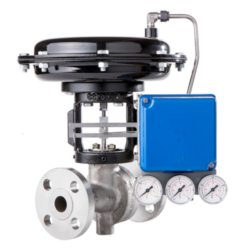

Contact us to learn about the Jordan Mark 70 sliding gate control valve for steam service in tire curing applications.

Let us help you find the right valve for your application.

Related Application Stories

Better Steam Pressure Control Improves Drying for Coating Process

Jordan Mark 701 Sliding Gate Control Valves give Tighter Temperature Control, Faster Throughput

Boiler Feedwater Control

Jordan Mark 33 feedwater control valve maintains accurate level in boiler steam drum.

How Temperature Regulators and Control Valves Work

Using Self-Operated Temperature Regulators to Control Steam

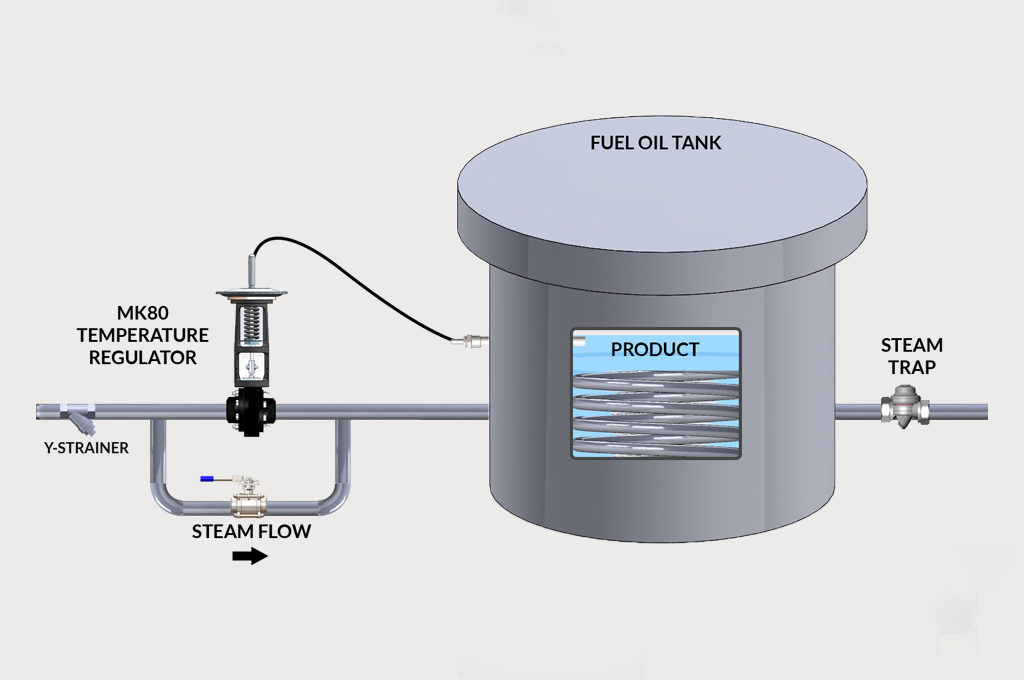

Steam Temperature Control of Jacketed Tanks

Steam pressure control is vital for maintaining consistent tank jacket temperature

Steam Curing Cinder Blocks

Accurate steam control for precision autoclave dryer performance

Steam Sterilization

Jordan Valve sliding gate valves with Jorlon® diaphragms outlast in challenging steam sterilizing process

Precision Steam Control

Jordan Sliding Gate Valve for Precise, Efficient Steam Control