Steam Sterilization

Jordan Valve sliding gate valves with Jorlon® diaphragms outlast in challenging steam sterilizing process

What is steam sterilization?

Steam sterilization is an essential procedure in medical, surgical, and dental practices as part of their decontamination and sterilization process. Steam sterilizers or autoclaves are made in a variety of sizes and styles to meet the needs of the healthcare profession. A key parameter for these autoclaves is the capability to control steam pressure and temperature accurately and consistently to meet the quality sterilization standards required in the health and research industries.

Case Study: How Jorlon® diaphragms improve reliability and life of steam sterilizer

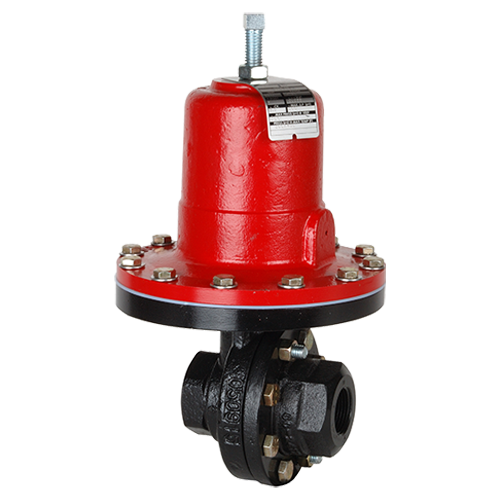

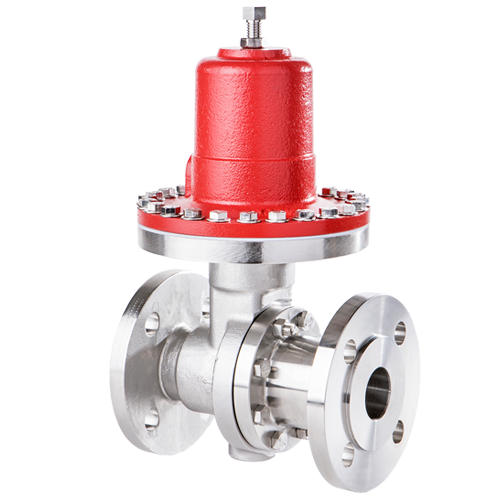

A large medical products company specializing in sterilization and surgical equipment approached Jordan Valve with a problem in their steam sterilization equipment. Their autoclaves incorporate self-actuating steam regulators to reduce hospital steam supply pressure down to an acceptable pressure range for safe use. The steam valves cycle frequently during the sterilization process to maintain a specific temperature over a duration of time and were often operating continuously. This continuous operation was resulting in frequent diaphragm failure in the steam regulators, as the only approved diaphragm material was 316 stainless steel. While a very good material overall, 316 stainless steel is not ideal for applications requiring constant flexion because it will fatigue and ultimately crack.

At the time, Jordan Valve had recently introduced a proprietary material known as Jorlon, a modified fluoropolymer plastic with superior durability, flexibility, temperature range and chemical compatibility. During product development, this material was tested by Jordan Valve engineers for more than one million cycles in steam service before introducing it to the market.

What is a Jorlon diaphragm? The last diaphragm you will ever need.

- Superior Chemical compatibility

- Outstanding performance at high pressures

- Excellent solution in steam applications

- Extremely long life and highly reliable

- Easily retrofitted with no additional parts

- Less expensive and lower cost of long-term ownership

The Jordan Valve sales team suggested this customer use Jordan Mark 60 valve with the new Jorlon diaphragm as a way to improve steam regulator service life and reduce maintenance on their autoclaves. The customer tested the Mark 60 regulators equipped with Jorlon in their on-site quality assurance laboratory, verifying the extraordinary properties of the new diaphragm option. The Jorlon diaphragm alternative was quickly approved as the preferred standard diaphragm material for the steam sterilizing equipment.

Since switching to the Jordan Mark 60 valve with the Jorlon diaphragm, this customer has not reported any material fatigue-related diaphragm failures and now incorporates a Jordan Mark 60 pressure regulator with every autoclave they sell.

Let us help you find the right valve for your application.

Related Resources

Precision Steam Control

Jordan Sliding Gate Valve for Precise, Efficient Steam Control

Steam Valve for Tire Curing Press

Jordan Valve sliding gate technology outperforms in challenging tire curing process

Better Steam Pressure Control Improves Drying for Coating Process

Jordan Mark 701 Sliding Gate Control Valves give Tighter Temperature Control, Faster Throughput

Boiler Feedwater Control

Jordan Mark 33 feedwater control valve maintains accurate level in boiler steam drum.

Steam Curing Cinder Blocks

Accurate steam control for precision autoclave dryer performance

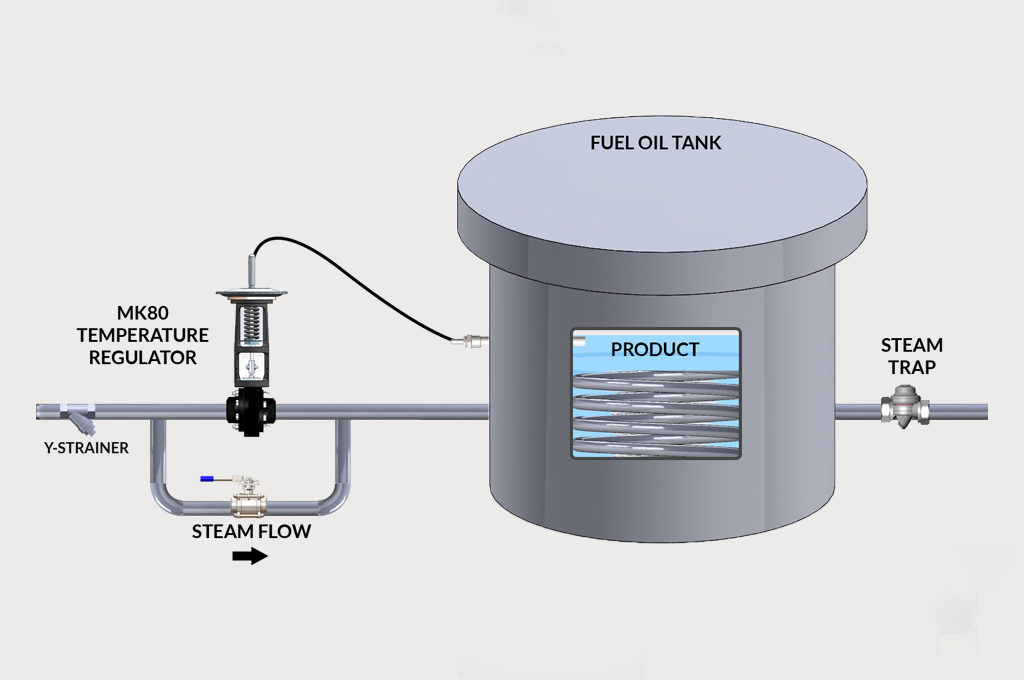

Steam Temperature Control of Jacketed Tanks

Steam pressure control is vital for maintaining consistent tank jacket temperature

How Temperature Regulators and Control Valves Work

Using Self-Operated Temperature Regulators to Control Steam

Mark 60 Series Self-Operated Sliding Gate Pressure Reducing Regulator

Mark 60 Series Self-Operated Sliding Gate Pressure Reducing Regulator  Mark 50 Series Self-Operated Sliding Gate Back Pressure Regulator

Mark 50 Series Self-Operated Sliding Gate Back Pressure Regulator