Valves for Tire Curing Press Applications

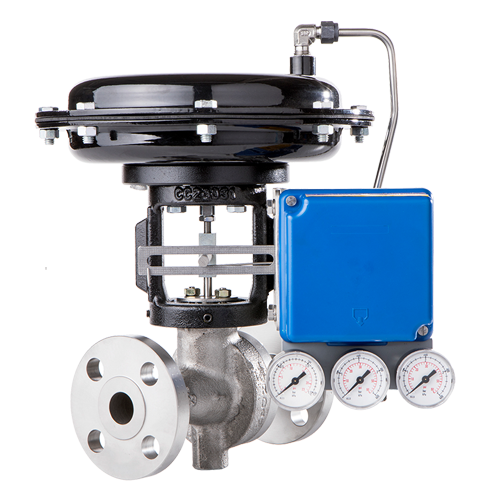

Mark 70 Series ⟶

Sliding Gate Diaphragm Control Valve

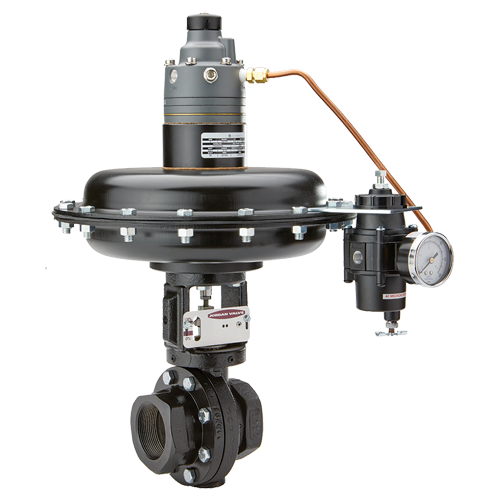

Mark 701/702 Series ⟶

Sliding Gate Control Valve for High Flow, Higher Cv's (Kv's)

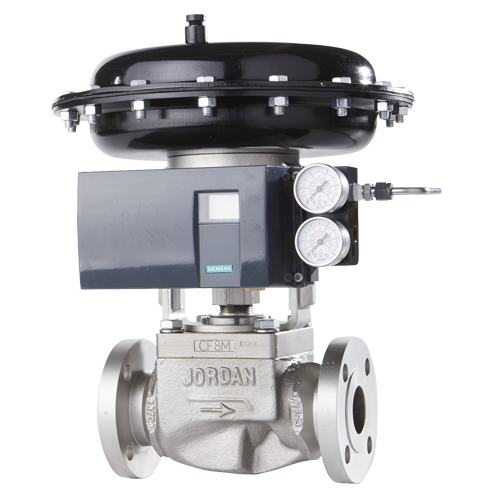

Mark 78 Series ⟶

Globe Style, Accurate Performance

Mark 75 Series ⟶

Wafer Style, Motor Operated, Very Precise

Mark 75HW Series ⟶

Wafer Style, Hand Operated, Precise Adjustment

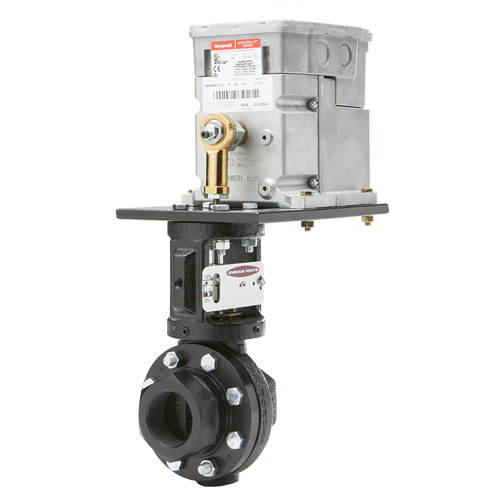

Mark 75MV Series ⟶

Wafer Style, Motor Operated Control Valve; Sliding Gate; 1″ - 8″ (DN25 - DN200)

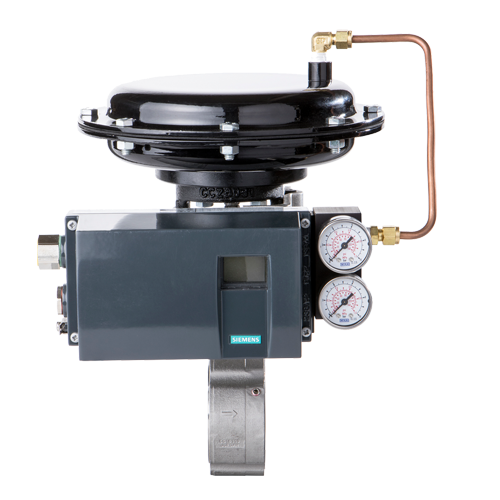

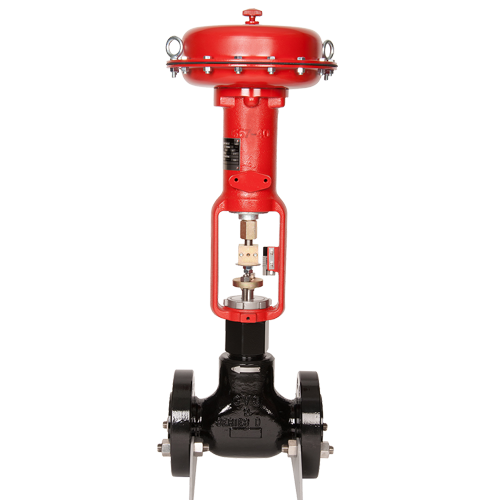

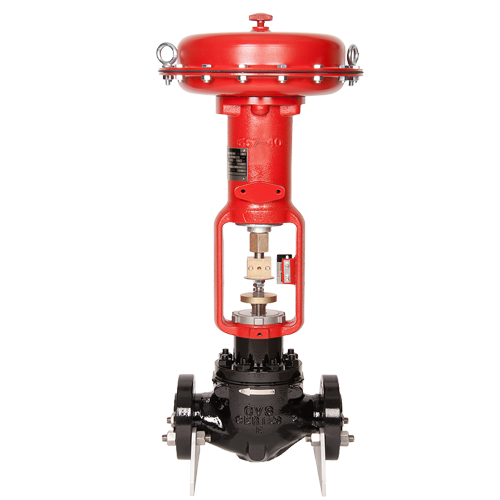

Mark 75PTP Series ⟶

Piston Operated with Smart Positioner

Mark 33 Series ⟶

Boiler Feedwater Control Valve; Motor Operated Sliding Gate; 1/4″ – 2″ (DN8 – DN50)

Mark 37 Series ⟶

Motor Operated Control Valve With Electronic Linear Actuator; 1/4″ – 6″ (DN8 – DN150)

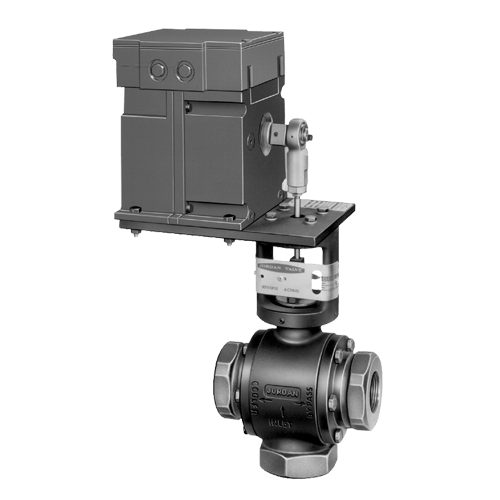

Mark 39 Series ⟶

Motor Operated Three Way

Mark DBAQ Series ⟶

Angle Style Control Valve

Mark CFR Series Pressure Reducing Filter Regulators ⟶

Filter Regulators

Mark D & DA Series ⟶

Globe & Angle Control Valve

Mark ED & ET Series (1″ – 6″) ⟶

Globe Style Control Valve

Mark ED & ET Series (8″) ⟶

Globe Style Control Valve

Mark EW Series ⟶

Globe Style Control Valves

Mark EZ Series ⟶

Globe Style Control Valve

Your List

Email List

Get A Quote

A tire curing press is used to mould and vulcanize green tires by applying controlled heat and pressure. The curing process relies on precise delivery of steam, hot water, oil, and nitrogen, making accurate valve performance essential for consistent quality, efficient cycle times, and equipment protection.

Jordan Valve products support tire curing operations by maintaining stable pressure and flow throughout the heating, pressurization, and cooling stages of the curing cycle.

Valve / Regulators for Tire Curing Press Systems

- Industrial Control Valves: Provide accurate flow control of steam, hot water, or thermal oil used to heat the mould. These valves help maintain consistent temperature profiles during the curing cycle.

- Globe Style Cage Guided Control Valves: Deliver precise modulation for critical heating or cooling loops, ensuring stable pressure and temperature control in high-demand curing applications.

- Wafer Style Control Valves: Offer compact flow regulation for auxiliary circuits, skid systems, and tight piping arrangements common in curing press installations.

- Electric Control Valves: Enable automated adjustments of pressure and flow based on curing sequences, sensor feedback, or PLC control. Ideal for presses requiring consistent, repeatable curing cycles.

Why Jordan Valve

Jordan Valve products provide the precise pressure and flow control needed for consistent tire curing. Our valves offer smooth modulation, tight shutoff, and reliable performance across steam, hot water, oil, and nitrogen systems used in tire curing presses.